Our Research & Development Center, recognized by the Italian Ministry of Education, University and Research, represents the core of the company’s innovation.

Located between Valfenera (Asti) and Villarbasse (Turin), it covers an area of over 2,500 m² and hosts a team of 30 highly specialized engineers.

They are dedicated to developing new products through an integrated process that combines CAE (Computer-Aided Engineering) methodologies, rapid prototyping, and soft tooling.

From virtual design to physical realization and experimental validation, our R&D Center ensures speed, precision, and innovation at every stage of development.

Product development

Our product development process complies with the requirements of the IATF 16949 standard and follows the APQP (Advanced Product Quality Planning) methodology to ensure full compliance with automotive customer specifications.

The main phases of the process include:

- Product design and planning (RFQ)

- Product development

- Product validation and manufacturing process design

- Process development and validation

- PPAP (Production Part Approval Process)

- Project and process review

Through a structured and interdisciplinary approach, we guarantee high standards of quality, reliability, and reduced time-to-market, turning every idea into a concrete, production-ready solution.

Engineering

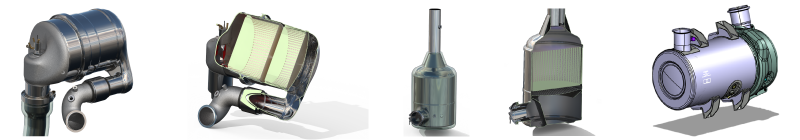

We specialize in the design and development of air intake systems, exhaust after-treatment systems, fuel and urea tanks, as well as a wide range of other components and systems for on-road and off-road applications

Our engineering activities combine advanced 3D modeling, simultaneous engineering, and state-of-the-art CAD tools such as CATIA and Siemens NX, enabling us to develop complex solutions with the highest efficiency and precision.

Through integrated processes, we shorten development cycles, optimize manufacturability, and ensure the quality and reliability of every project.

Virtual simulation

By leveraging advanced CAE tools and virtual simulation techniques, we explore and validate every design solution in a digital environment.

This approach allows us to anticipate real-world performance, drastically reduce development times, and optimize design before building the first prototype.

The result: smarter, faster, and predictive processes.

Prototypes

We have an in-house department dedicated to prototype construction, equipped with rapid prototyping and soft tooling technologies that enable the production of fully representative samples of future serial parts in extremely short lead times

This internal capability allows us to accelerate project validation and conduct experimental testing on components and systems at an early stage of development.

The integration between virtual design and physical prototyping ensures shorter timelines, greater flexibility, and full control over the development process.

Testing

Our Research Center is equipped with a wide range of facilities and laboratories dedicated to the validation of prototype components and systems, allowing us to test performance under controlled and reproducible conditions.

Our equipment includes:

- Flow benches for fluid-dynamic and functional characterization.

- Electrodynamic shakers and fatigue test benches for structural and durability testing;

- Climatic chambers, salt spray cells, and pressure test benches for strength and sealing verification;

- High-temperature ovens and dynamometers for thermal and performance tests.

We also collaborate with specialized external centers:

- TRP for shaker tests at hot temperature and on three axes;

- STSe for hot-flow testing and exhaust gas emission analysis.

Thanks to this comprehensive testing infrastructure, we can reproduce real operating conditions, optimize design, and validate technical solutions before starting serial production.

|

Innovation

We continuously invest in Research and Development, allocating around 3.5% of our annual turnover to product and process innovation.

Over the past decade, we have filed more than 50 patents, demonstrating our ongoing commitment to developing advanced technological solutions.

Since 2013, we have been collaborating with the Politecnico di Torino, actively participating in research projects and supporting theses, internships, and PhD programs to foster the growth of new engineering talent.

Our most significant innovations include the urea static mixer for SCR exhaust after-treatment systems and the urea Sender Unit with an integrated quality sensor, designed to improve the efficiency and reliability of emission control systems.

An outstanding example in the field of alternative energy is our battery cooler, developed for the thermal management of electric vehicle batteries.

By combining internal research, academic collaboration, and a forward-looking vision, we anticipate customer needs and contribute to the technological evolution of the mobility sector.

Global Presence

Our international presence extends across Italy, Poland, Romania, Turkey, Canada, Brazil, India, and China, providing a strategic coverage of major global markets.

This integrated engineering and manufacturing network enables us to operate worldwide while maintaining customer proximity, fast delivery, and consistent quality across all sites.

Thanks to a flexible and connected industrial model, we can develop, validate, and produce technological solutions that meet global automotive industry standards, supporting our partners anywhere in the world.

Partnership

Cornaglia cooperates with the main Italian and European technical universities and research institutes.

Consolidated partnerships with selected suppliers allows us to access the latest product innovation and solutions even before they reach the market.